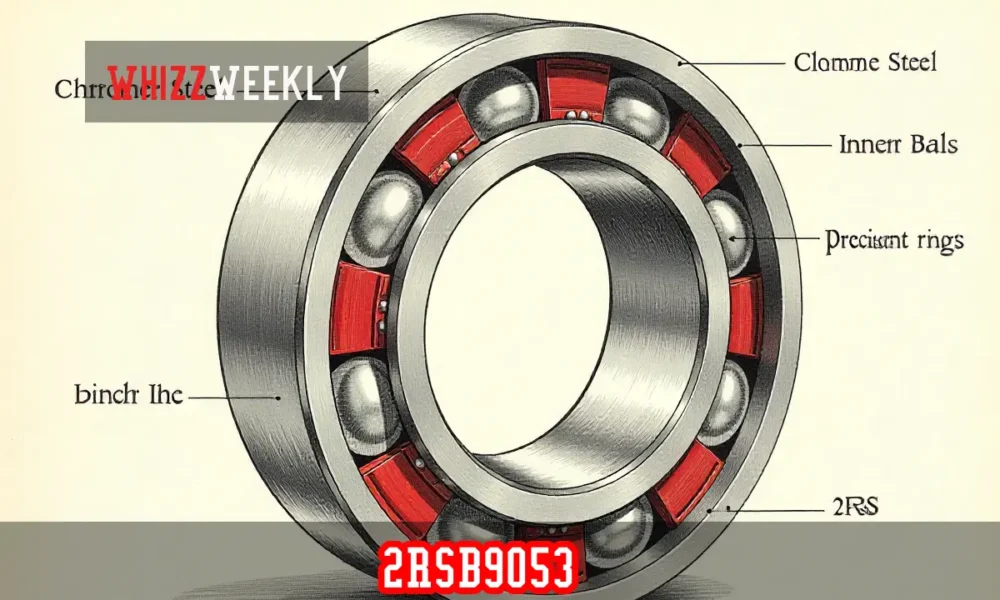

2RSB9053: What Makes This Bearing Essential for Modern Machinery?

The 2RSB9053 is a double-sealed deep groove ball bearing designed for high-performance applications. The “2RS” indicates rubber seals on both sides that protect against contaminants, while “B9053” specifies its size series. This bearing handles both radial and axial loads with minimal friction, making it ideal for industrial machinery, automotive systems, and precision equipment.

Understanding the 2RSB9053 Code Structure

The alphanumeric code 2RSB9053 contains specific technical information. Each segment reveals key design features that define this bearing’s capabilities.

The “2RS” prefix indicates double rubber seals installed on both sides of the bearing. These seals prevent dust, dirt, and moisture from entering the internal chamber while keeping lubricants contained. This design extends operational life and reduces maintenance requirements significantly.

The letter “B” typically identifies the bearing type as a deep groove ball bearing. This category handles both radial loads perpendicular to the shaft and moderate axial loads parallel to it.

The numeric sequence “9053” represents the size series and dimensional specifications. These standardized codes allow engineers to identify correct replacements quickly without confusion.

Technical Specifications That Matter

The 2RSB9053 bearing consists of high-grade chrome steel rings that resist wear, corrosion, and metal fatigue. The construction includes precision steel balls arranged between inner and outer rings, maintaining uniform contact under varying load conditions.

Most 2RSB9053 bearings come pre-lubricated with high-performance grease. This means you get maintenance-free operation throughout most of the bearing’s service life. The lubrication remains sealed inside, protected from contamination by the double rubber shields.

Speed ratings vary by manufacturer but generally support both high-speed rotation and heavy load applications. Temperature tolerance typically ranges from -30°C to +110°C for standard configurations, though specialized versions handle wider ranges.

The bearing’s osculation ratio—where balls contact the raceway—typically falls between 0.51 and 0.54. This high degree of contact provides superior load-bearing capacity compared to bearings with lower osculation values.

How Double Sealing Transforms Performance

The 2RS sealing system represents a critical advantage. Contact seals made from high-performance nitrile rubber with reinforced steel cases create barriers against external contaminants.

This dual protection serves two purposes simultaneously. First, seals block dust, moisture, and chemical particles from reaching internal components. Second, they prevent lubricant loss during operation, even under vibration or temperature changes.

Sealed bearings dramatically enhance lifespan, reduce friction, and ensure consistent performance in dusty, wet, or chemically harsh environments. The sealed design makes 2RSB9053 particularly valuable in outdoor applications, food processing equipment, and manufacturing facilities with airborne particles.

Primary Applications Across Industries

Aerospace and Aviation

Aircraft use 2RSB9053 bearings in actuators, stabilizers, and flight control systems where consistent performance under variable load and temperature proves essential. The sealed design prevents failures caused by airborne particles and extreme pressure changes at altitude.

Industrial Automation

Robotic arms, CNC machinery, and automated assembly lines demand precision. The 2RSB9053 provides smooth rotation with minimal vibration, directly improving accuracy in manufacturing processes. Its durability reduces maintenance intervals, keeping production lines running longer between service stops.

Automotive Systems

The automotive industry relies on these bearings for gearboxes, electric motors, and steering mechanisms due to resistance to heat, moisture, and heavy load-bearing capacity. This contributes to extended vehicle life and more efficient operation across diverse driving conditions.

Medical Equipment

Medical devices require components that function quietly and precisely, making the sealed 2RSB9053 suitable for diagnostic machines, surgical tools, and patient-handling equipment. The contamination protection ensures sterile operation in clinical environments.

Electric Motors and Pumps

Deep groove ball bearings are commonly used in electric motors, compressors, fans, and conveyors, utilized in mechanical applications across most industries. The 2RSB9053’s low-friction characteristics reduce energy consumption while maintaining consistent rotational speed.

Why Engineers Choose 2RSB9053

Low Friction Operation: This bearing type has low friction and can operate over a wide range of speeds. The deep groove design allows balls to maintain optimal contact angles, minimizing resistance during rotation.

Bidirectional Load Handling: Unlike some bearing types, the 2RSB9053 accommodates axial loads in both directions simultaneously while supporting primary radial loads. This versatility eliminates the need for additional thrust bearings in many applications.

Reduced Maintenance: Pre-lubrication combined with sealed protection means you can install and forget. Most applications require no relubrication throughout the bearing’s operational life.

Quiet Operation: The precision manufacturing tolerances reduce vibration and noise levels. This makes the 2RSB9053 ideal for environments where sound control matters—hospitals, offices, or residential equipment.

Temperature Stability: The bearing maintains performance across significant temperature ranges. This thermal stability prevents premature failure in applications with varying operational conditions.

Installation and Selection Considerations

Getting the right bearing requires attention to several factors. First, verify dimensional compatibility. The bore diameter must match your shaft precisely, while the outer diameter must fit your housing without excessive clearance.

Material quality directly impacts longevity. Look for bearings manufactured from certified chrome steel or stainless steel variants for corrosion-prone environments. Request material certifications from suppliers to ensure quality standards.

Check load ratings against your application requirements. Calculate both radial and axial loads your system will experience, then select a bearing with adequate capacity plus a safety margin.

Tolerance class determines precision levels. Higher precision bearings cost more but provide smoother operation with less vibration. Match tolerance to your application needs—industrial machinery often uses standard tolerance, while precision instruments require tighter specifications.

Speed limits vary by bearing size and lubrication type. Deep groove ball bearings are suitable for high-speed applications. However, sealed bearings typically operate at 50-60% of open bearing speed ratings due to seal friction.

Common Mistakes to Avoid

Using incorrect installation tools causes bearing damage before operation begins. Never hammer directly on bearing surfaces. Use proper bearing drivers or hydraulic presses that apply force evenly.

Over-tightening mounting bolts creates stress points that lead to premature failure. Follow manufacturer’s torque specifications exactly.

Ignoring shaft and housing tolerances creates problems. Too tight a fit causes excessive preload and heat buildup. Too loose a fit allows movement that wears mating surfaces.

Mixing incompatible lubricants when adding supplementary grease can cause chemical breakdown. Stick with the same grease type used in factory pre-lubrication.

Performance Monitoring and Replacement Indicators

Regular monitoring extends bearing life by catching problems early. Listen for unusual noise changes—grinding, squealing, or clicking indicate potential issues.

Temperature increases beyond normal operational ranges signal inadequate lubrication, excessive load, or internal damage. Use infrared thermometers for non-contact monitoring.

Vibration analysis detects imbalance or wear patterns before catastrophic failure. Handheld vibration meters provide quick assessments during routine inspections.

Replace bearings when performance degrades noticeably. Continuing operation with damaged bearings risks secondary damage to shafts, housings, and connected components.

Sourcing Quality 2RSB9053 Bearings

Purchase from authorized distributors who provide manufacturer documentation. Counterfeit bearings lack quality control and fail prematurely, costing more in downtime than initial savings.

Request technical datasheets showing exact specifications. Reputable suppliers provide detailed information, including dimensional tolerances, load ratings, and speed limits.

Verify packaging integrity upon delivery. Damaged packaging may indicate improper storage or handling that compromises bearing performance.

Consider the total cost of ownership rather than just the purchase price. A slightly more expensive bearing from a reliable manufacturer often provides better value through extended service life and reduced maintenance.

Frequently Asked Questions

What does 2RS mean in bearing codes?

2RS indicates double rubber seals on both sides of the bearing, protecting internal components from contaminants while retaining lubrication.

Can 2RSB9053 handle both radial and axial loads?

Yes, deep groove ball bearings accommodate radial loads and moderate bidirectional axial loads simultaneously, making them highly versatile.

How long does a 2RSB9053 bearing typically last?

Service life depends on operating conditions, but properly installed sealed bearings often run maintenance-free for several years under normal loads.

Are sealed bearings slower than open bearings?

Sealed bearings typically operate at 50-60% of open bearing speeds due to seal friction, but provide superior contamination protection.

What temperature range can 2RSB9053 handle?

Standard configurations operate from -30°C to +110°C, with specialized versions available for extended temperature ranges.