RepMold: The Smart Manufacturing Solution That’s Changing How We Make Things

Manufacturing just got a major upgrade. While traditional mold-making crawls along with weeks-long timelines and sky-high costs, RepMold swoops in like your manufacturing wingman. This tech combines rapid prototyping with precision molding to create exact copies faster than you can say “production deadline.”

Think of RepMold as the cheat code for modern manufacturing. It takes the headaches out of mold creation while keeping quality tight. Your production line stays moving, costs stay reasonable, and your customers stay happy. That’s the kind of manufacturing magic every business needs right now.

What Makes RepMold Different From Traditional Molding

RepMold flips the script on how we think about mold-making technology. Traditional methods require extensive design phases, multiple iterations, and significant material waste throughout the entire process. RepMold streamlines this workflow by combining digital design tools with rapid prototyping capabilities for faster results.

The speed difference hits you immediately. Where conventional molding takes weeks to produce a single prototype, RepMold delivers in days. This acceleration comes from smart material use and streamlined processes that cut out unnecessary steps. Your design team can test, refine, and finalize products without those painful delays.

Cost savings stack up quickly with this approach. Less material waste means lower expenses per unit produced during manufacturing runs. Labor costs drop because the process requires fewer manual interventions and quality control checkpoints. Engineering teams can focus on innovation rather than troubleshooting production bottlenecks.

Quality remains consistently high across all production batches. RepMold maintains tight tolerances and precise specifications throughout the manufacturing cycle. Each component matches the original design requirements without the variability common in traditional molding methods.

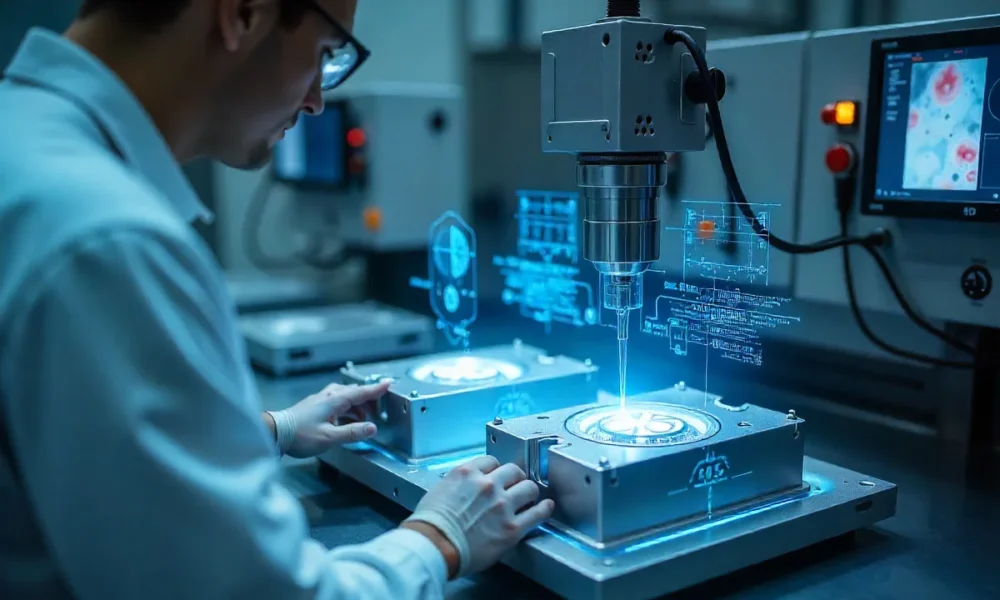

How RepMold Technology Actually Works

The process starts with computer-aided design software that creates precise digital models. Engineers input specifications, material requirements, and performance parameters into the system for accurate prototyping. This digital foundation ensures consistency from the first prototype through full-scale production runs.

Rapid prototyping takes center stage during the development phase. 3D printing, CNC machining, or other additive manufacturing techniques create physical prototypes quickly and cost-effectively. Teams can test functionality, fit, and performance before committing to expensive tooling investments.

Material selection becomes more flexible with RepMold systems. Plastics, metals, composites, and specialized materials work within the same framework for diverse applications. This versatility lets manufacturers adapt to different project requirements without changing their entire production setup.

Quality control happens throughout the process rather than just at the end. Sensors monitor temperature, pressure, and material flow during molding operations for consistent results. Digital tracking systems record every parameter, making it easy to replicate successful production runs exactly.

Final parts undergo testing to verify they meet specifications. Strength, durability, and performance characteristics get measured against design requirements for quality assurance. This systematic approach catches issues early and prevents costly recalls or customer complaints later.

Industries Getting Real Results With RepMold

Automotive manufacturers use RepMold for engine components, dashboard parts, and custom interior pieces. The technology speeds up prototype development for new vehicle models while maintaining the precision required for safety compliance. Production costs drop significantly compared to traditional tooling methods.

Medical device companies rely on RepMold for surgical instruments, diagnostic equipment housings, and custom prosthetics. The precision requirements in healthcare make this technology particularly valuable for creating life-saving equipment. Regulatory compliance becomes easier with consistent, documented production processes.

Aerospace engineering demands lightweight components with exact specifications and zero tolerance for defects. RepMold delivers both requirements while reducing development time for critical aircraft parts. The technology supports complex geometries that traditional molding struggles to achieve reliably.

Consumer electronics benefit from RepMold’s ability to create small, intricate parts quickly. Smartphone cases, connector housings, and internal components can be prototyped and manufactured efficiently. Market response time improves when products reach consumers faster than competitors.

Cost Benefits That Actually Matter

Material waste drops by up to 40% compared to traditional molding methods. RepMold optimizes material use during production, reducing the raw materials needed per finished component. This efficiency translates directly into cost savings for every production run.

Labor costs decrease because RepMold requires fewer manual operations throughout the manufacturing process. Automated systems handle most production tasks, freeing skilled workers for higher-value activities like design and quality improvement. Training requirements also drop since the technology simplifies many complex procedures.

Setup times shrink dramatically when switching between different products or design variations. Traditional molding requires extensive retooling for product changes, while RepMold adapts quickly to new specifications. This flexibility reduces downtime and increases overall equipment effectiveness.

Quality issues cost less to fix when caught early in the RepMold process. Digital monitoring and rapid prototyping identify problems before full production begins, preventing expensive recalls. The consistent quality also reduces warranty claims and customer service expenses.

Energy consumption stays lower throughout production cycles. RepMold systems operate more efficiently than traditional molding equipment, reducing utility costs per unit manufactured. Environmental compliance becomes easier with lower energy use and reduced waste generation.

Common Mistakes to Avoid With RepMold

Skipping proper material testing leads to production failures and wasted resources. Different materials behave uniquely in RepMold systems, requiring specific parameters for optimal results. Run small test batches before committing to large production volumes.

Inadequate design optimization causes unnecessary complexity and higher costs during manufacturing. RepMold works best with designs that take advantage of its capabilities rather than copying traditional approaches. Work with experienced engineers who understand the technology’s strengths and limitations.

Poor maintenance schedules reduce equipment reliability and part quality over time. RepMold systems need regular cleaning, calibration, and component replacement like any manufacturing equipment. Preventive maintenance costs less than emergency repairs and production shutdowns.

Insufficient operator training creates safety hazards and reduces production efficiency. RepMold technology requires specific skills and knowledge for safe, effective operation. Invest in proper training programs and ongoing education for your manufacturing team.

Getting Started With RepMold Implementation

Assess your current production needs and identify applications where RepMold offers clear advantages. Look for products with complex geometries, frequent design changes, or high precision requirements. These applications typically see the biggest benefits from RepMold technology adoption.

Partner with experienced RepMold specialists who understand your industry requirements and production goals. Their expertise helps avoid costly mistakes during implementation and ensures optimal system configuration. Choose suppliers with proven track records in your specific manufacturing sector.

Start small with pilot projects that demonstrate RepMold’s value without major capital investment. Test the technology on existing products to validate performance before expanding to new applications. This approach reduces risk while building internal expertise and confidence.

Plan for training and skill development within your manufacturing organization. RepMold requires different skills than traditional molding, so invest in education for operators and engineers. Consider ongoing support agreements with technology providers for complex troubleshooting and optimization guidance.

Future of Manufacturing With RepMold

Artificial intelligence integration will make RepMold systems even smarter and more efficient. Machine learning algorithms will optimize process parameters automatically, reducing waste and improving quality consistently. Predictive maintenance will prevent equipment failures before they disrupt production schedules.

Material science advances will expand RepMold capabilities into new applications and industries. Advanced composites, biodegradable polymers, and specialized alloys will become easier to process reliably. This expansion opens opportunities in sectors like renewable energy and sustainable packaging.

Industry 4.0 connectivity will link RepMold systems with enterprise resource planning and supply chain management. Real-time production data will enable better demand forecasting and inventory optimization throughout manufacturing organizations. Digital twins will allow virtual testing before physical production begins.

Sustainability requirements will drive further RepMold adoption as companies seek to reduce environmental impact. Lower material waste, reduced energy consumption, and local production capabilities align with corporate sustainability goals. Regulatory pressure will accelerate this transition across multiple industries.